Ghezzi Renzo Srl is a mechanical turnery specialising in high-precision machining that offers services for different industrial sectors. Our machining is mainly divided into two areas: milled turned parts and tilted machining.

We process a wide range of materials, including AVP steel, alloy steel and tempered steels, brass, aluminium, copper, nylon, delrin, PVC and stainless steels. Our core competence is in the machining of alloy and stainless steels, where we perform milling, drilling, and tilted machining with tight precision tolerances.

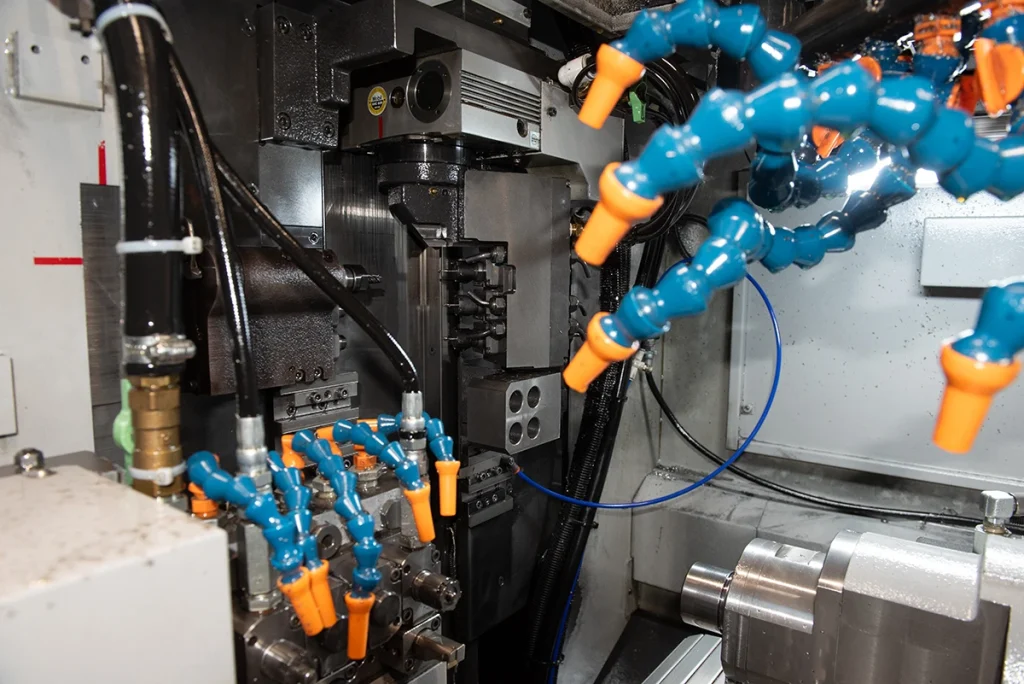

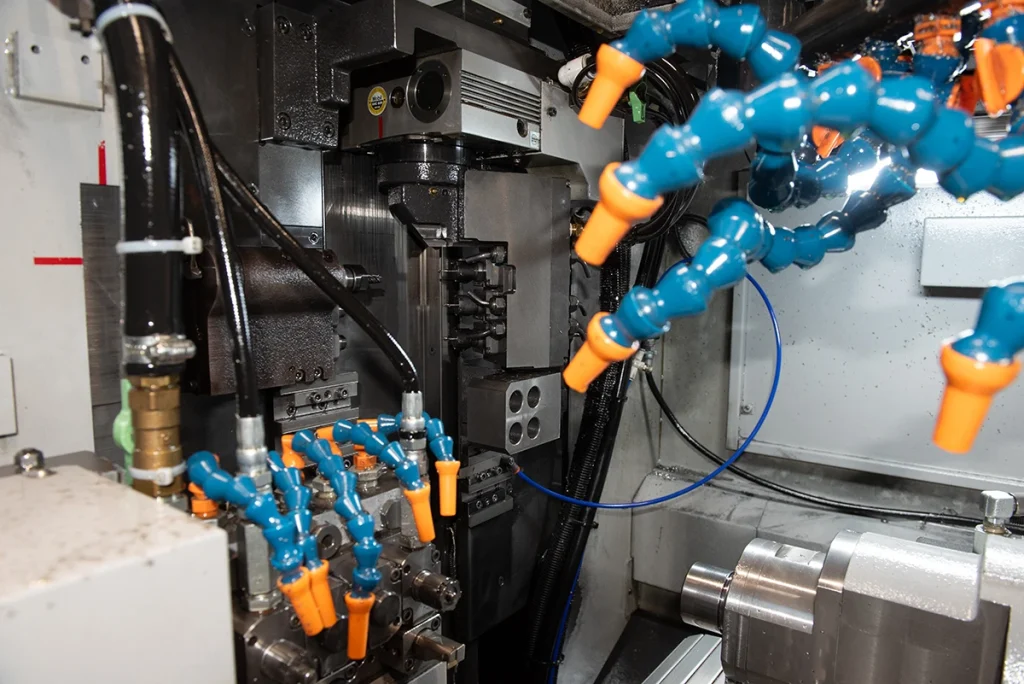

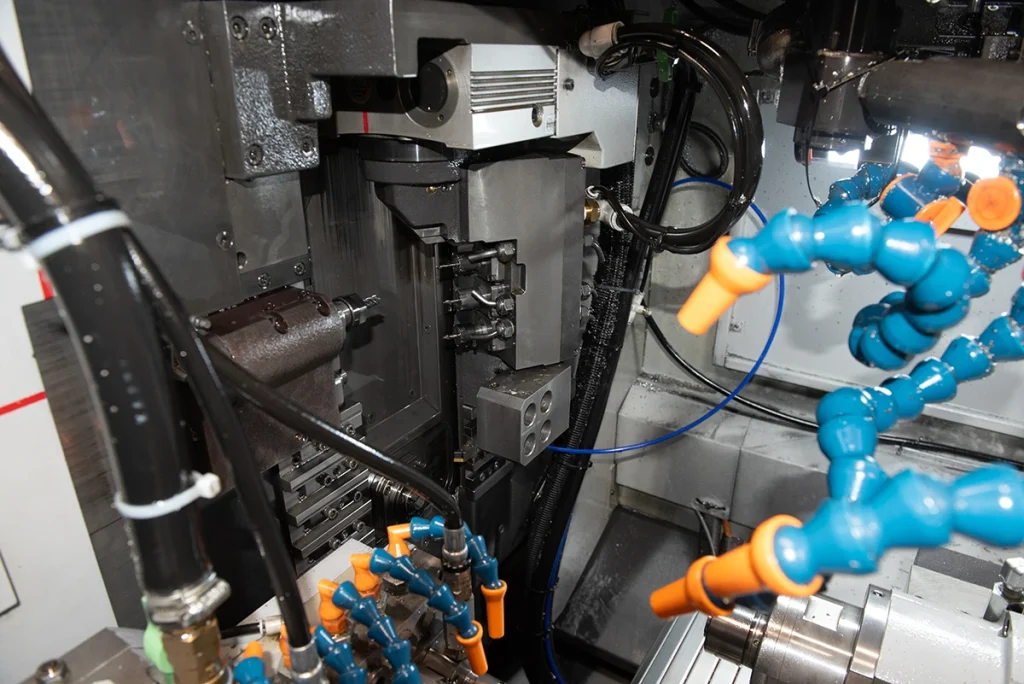

We use cutting-edge CNC lathes and milling machines, which allow us to produce complex components with very tight tolerances.

Each job is performed with meticulous attention to detail and undergoes stringent dimensional inspections, thus guaranteeing high quality standards. Our experience and technology enable us to tackle even the most demanding challenges, ensuring speed and precision in every project.

Turned and milled parts represent one of our main specialisations. Thanks to the use of cutting-edge CNC lathes, we are able to carry out high-precision machining on alloy and stainless steels, while maintaining very tight tolerances.

We use CNC milling machines to guarantee detailed and complex machining, adaptable to specific project requirements.

Our CNC lathe with barfeeder and lathe for secondary turning allow us to produce high quality components quickly.

Every part produced is subjected to stringent dimensional inspection, thanks to the use of advanced technologies such as the KEYENCE IM7500 profile projector.

Tilted machining requires special attention and specialised skills.

Our expertise enables exceptional precision in tilted machining across a range of materials.

Tilted machining requires special attention and specialised skills. Our experience allows us to perform tilted machining on different materials with unparalleled accuracy.

We are able to adapt our machining techniques to the customer's specific needs, offering customised solutions.

Our attention to detail and the use of high-precision machinery ensure that each component adheres to the highest quality standards.